This website uses cookies to enhance your experience and allow us to see how the site is used. To continue to use this site using cookies, please click ACCEPT below.

Learn more about our cookies policy. TCDC has many successful applications for some of the biggest players in the automotive industry. All three of TCDC’s US facilities are IATF 16949:2016 and ISO 14001 certified. APQP planning and PPAP process are standard procedures for TCDC. Automated robotic cast cells, and vertical and horizontal machining centers (capable of close tolerance machining), are combined with our inline vision systems and pressure testing, to facilitate the production of consistently high quality components. The automotive industry will also benefit from our multi-cavity expertise to meet the high volume demand.

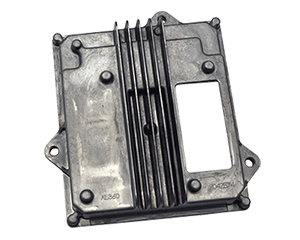

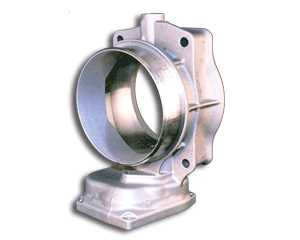

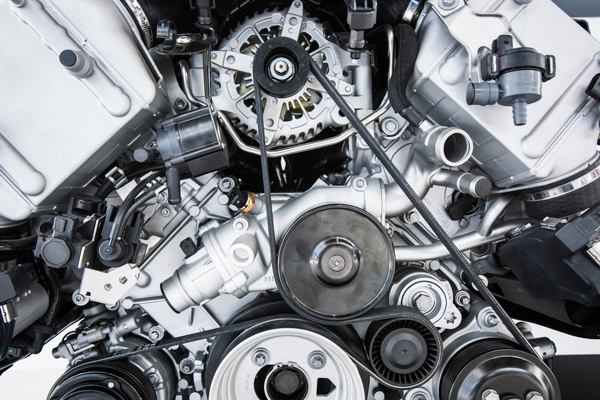

TCDC has many successful applications for some of the biggest players in the automotive industry. All three of TCDC’s US facilities are IATF 16949:2016 and ISO 14001 certified. APQP planning and PPAP process are standard procedures for TCDC. Automated robotic cast cells, and vertical and horizontal machining centers (capable of close tolerance machining), are combined with our inline vision systems and pressure testing, to facilitate the production of consistently high quality components. The automotive industry will also benefit from our multi-cavity expertise to meet the high volume demand.Common applications include Electronic Enclosures, Throttle Bodies, EGR’s, Transmission Control Modules, Exterior Mirror Housings, Fan Drives, and Variable Speed Fan Clutch Housings. TCDC is also committed to the fast-growing Electric Vehicle (EV) Market and electronic technologies used in Advanced Driver Assistance Systems (ADAS) such as Lighting Heatsinks, Brackets, Information Systems, Surround View Cameras, IP Structural Castings, & Onboard Charging.