This website uses cookies to enhance your experience and allow us to see how the site is used. To continue to use this site using cookies, please click ACCEPT below.

Learn more about our cookies policy.

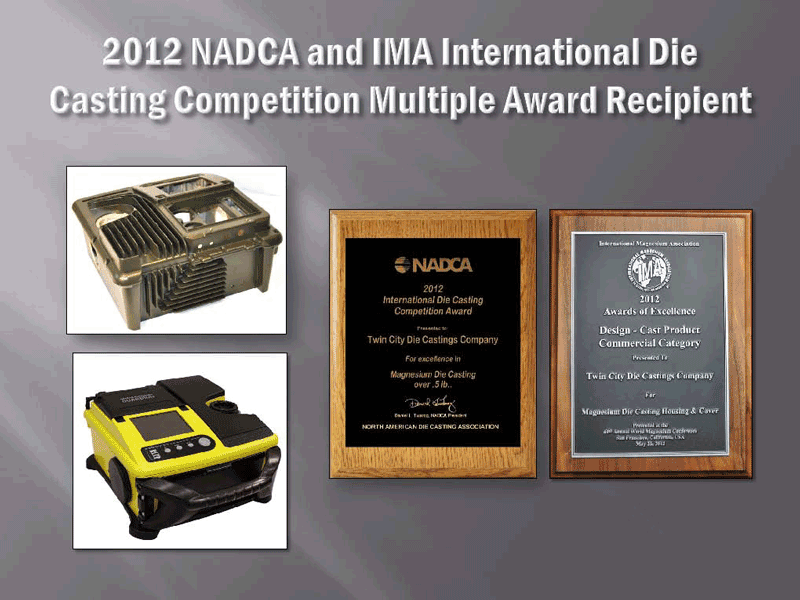

2012 NADCA Die Casting Design Competition - Magnesium Die Casting over 0.5 lbs.

Alloy: AZ91

Industry: Homeland Security/Defense

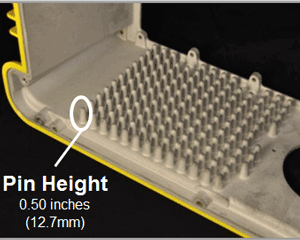

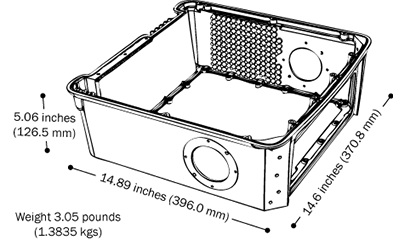

Main Enclosure Casting: The customer desired that internal pins be as cast, rather than a separate piece.

Using an internal lift, TCDC was able to cast internal heat sink pins as part of the casting. The alternate method was to cast a separate piece and fasten it to the casting - which would have added cost and would not have had as good of heat sink properties. The large center opening allowed both a lift and a center gated casting to aid fill on fins and pins. Minimum draft on all features help to keep the weight under design limits.

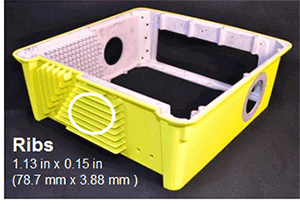

• Cast a one piece housing with external ribs as heat sinks.

• Center gating allows optimal fill.

• Minimal draft on ribs (1 deg / side), and thin wall design reduces weight.

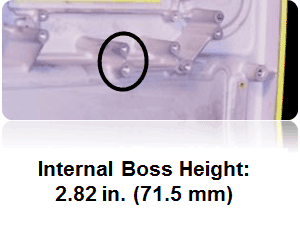

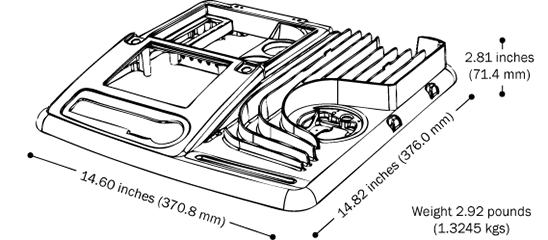

Top Plate Casting: Deep internal bosses on the cover with Minimum draft made casting almost equal in surface area between the inside and out. The solution was to apply a double ejector system to both the Ejector half and cover half cavities.

Design Properties: The Top Plate required additional ribs to help meet heat sink properties needed. Both the Main Enclosure and Top Plate have limited draft of 1 degree per side on fins as well as thin wall design to minimize weight.