This website uses cookies to enhance your experience and allow us to see how the site is used. To continue to use this site using cookies, please click ACCEPT below.

Learn more about our cookies policy.

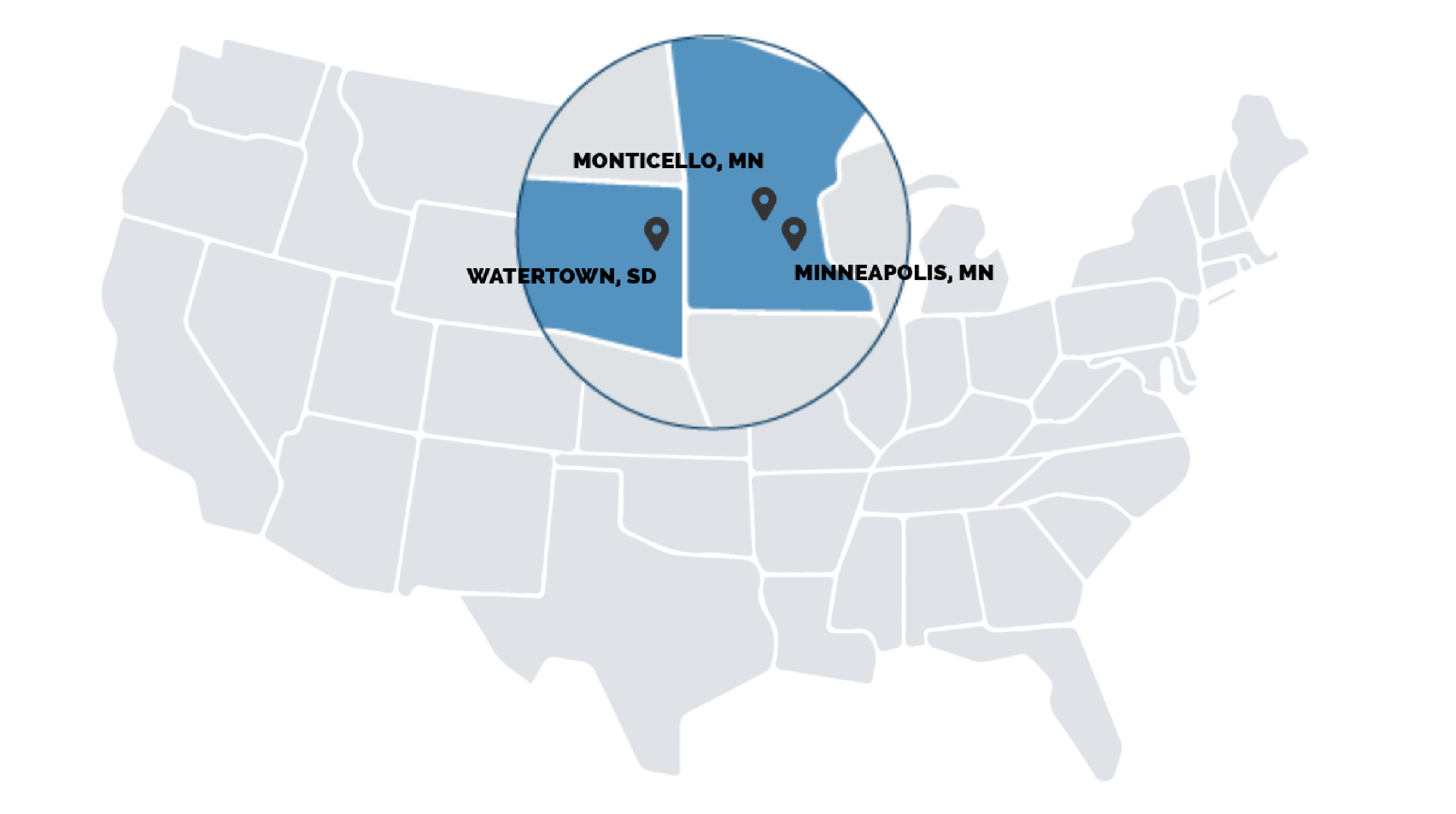

TCDC operates three US facilities in the Midwest located within 200 miles of the corporate headquarters of Minneapolis, Minnesota. All locations conform to the IATF 16949:2016 Quality Management System Standard, ISO 14001:2015 Environmental Management Standard, and the ISO 45001:2018 Occupational Health and Safety Management System Standard. Die casting capabilities range from 300 to 1000 tons, supported by Buhler and Colosio cold-chamber die casting machines along with Metal Mechanics trim presses, Rauch magnesium furnaces, and ABB and Reis robots. Using state of the art equipment provides efficiency and repeatability in the production of high quality aluminum and magnesium castings. As with all TCDC locations, tight tolerance machining is an integral part of our operations and can be incorporated to meet your precise design standards.

1070 33rd Avenue SE

Minneapolis, MN 55414

Phone: 651-645-3611

Our Minneapolis location is home to aluminum die casting and secondary operations, including CNC machining, finishing and assembly. Some of the specialties in the 74,000 sq. ft. Minneapolis plant include multiple cavity dies (up 18 cavities), close tolerance machining, and experience with a wide range of finishing options.

122 Cessna St. NW

Watertown, SD 57201

Phone: 605-886-9448

In 1989, TCDC expanded to Watertown, South Dakota. Located approximately 200 miles from the Twin Cities, operating 65,000 sq. feet of space, the Watertown facility is dedicated to running fully automated aluminum die cast cells. Automated machining lines with robots and in-cell pressure testing are a few of the many items that separate our Watertown plant from other die casters.

520 Chelsea Rd.

Monticello, MN 55362

Phone: 763-271-5060

In 2000, we opened up our newest plant in Monticello, Minnesota to serve the growing need for magnesium die castings. Located 40 miles from TCDC's headquarters, this state-of-the art plant is 45,000 sq. ft. and is equipped with the most technologically advanced equipment in the world. The Monticello location has made a name for itself in cosmetic parts with class “A” finishes and thin wall die castings.